A team of Japanese researchers from Yokohama University has developed a new electrode for lithium-ion batteries that power electric vehicles that could see them cost less to make, deliver a longer driving range, and even last longer.

Electric vehicles are increasingly seen as one answer to the challenges of climate change, as they emit zero tailpipe emissions and are more efficient with energy than petrol and diesel vehicles, even when the electric vehicles are powered off a coal-fired grid.

Add renewable energy sources to the mix and you have a truly carbon free form of transport.

Considering transport make up around 20% of Australia’s entire carbon footprint, it’s a benefit that could have a significant and positive impact.

But holding electric vehicles back is the high price of batteries, which can be valued at as much as 30% of the entire cost of a car, partly because of the use of expensive materials such as cobalt in the batteries.

The new research, which was published in Materials Today, describes a new electrode material using titanium and manganese, which are both plentiful and therefore more affordable.

“Electrode materials with higher energy density are needed to advance lithium ion batteries and to further develop electric vehicles,” said Naoaki Yabuuchi, professor at Yokohama University who lead the research, in a statement.

“Our paper demonstrates a new electrode material for this purpose.”

Electrodes are the “heart” a battery – they transform stored energy and allow it to be discharged to power a device, such as an electric car. How well the electrons and lithium ions are exchanged has a direct effect on the efficiency of a battery – much like how well a heart pumps blood around the body.

Previous studies have shown that a combination of manganese, titanium and oxygen ions mixed with lithium ions could increase the input-output of energy in a battery but that the ions exchanged too slowly for this combination to be of use.

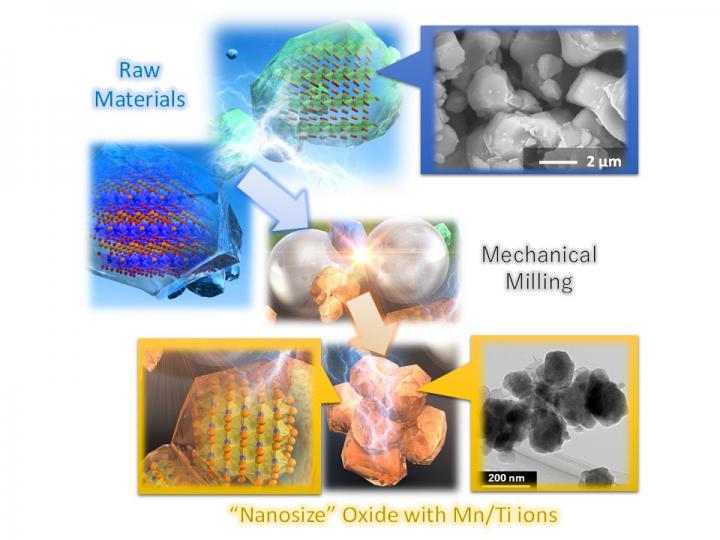

However, the new research shows that by “micro-milling” the materials down to nano-size, the particle can travel more quickly – even at room temperature. The result is a “more robust exchange”, say the researchers, allowing the battery to hold and disperse more energy, at the same time as prolonging the battery’s life cycle.

As this combination uses more common materials, it would also make lithium-ion batteries cheaper to make.

“Both titanium and manganese are abundant elements, meaning we can make cost-effective, without nickel and cobalt ions used for current electric vehicles, and high-performance electrode materials with them,” Yabuuchi says.

“This finding contributes to the reduction of battery cost and an increase in the practical reality of such applications as electric vehicles and more.”

The research was supported by the Japan Society for the Promotion of Science, the Ministry of Education Culture, Sports, Science and Technology and the Japan Science and Technology Agency, and next steps are to work with industry for potential commercialisation.

“Now, we are collaborating with industry partners to utilize our electrode materials for practical applications,” Yabuuchi says.

“Our study potentially leads to less dependence on fossil fuels and the development of a new energy society on the basis of renewable energy in the future, on the basis of ever-lasting, high-energy batteries.”

Bridie Schmidt is associate editor for The Driven, sister site of Renew Economy. She has been writing about electric vehicles since 2018, and has a keen interest in the role that zero-emissions transport has to play in sustainability. She has participated in podcasts such as Download This Show with Marc Fennell and Shirtloads of Science with Karl Kruszelnicki and is co-organiser of the Northern Rivers Electric Vehicle Forum. Bridie also owns a Tesla Model Y and has it available for hire on evee.com.au.